Neon LED tube lights are some of the most popular and versatile lighting fixtures on the market today. They are great for adding light to a public space or making a home more comfortable. Unfortunately, there are a lot of different colors, shapes, and sizes of LED neon lights, which makes it hard to choose. In this in-depth guide, you’ll learn everything you need to know about LED neon lights.

How do old-fashioned neon lights work?

They are made of electrified glass tubing or lamps filled with neon gas. Neon tubes are made of a low-pressure gas-filled glass cylinder that has been sucked dry and has electrodes on both sides. When several thousand volts are applied to the electrodes, the gas inside the tube becomes ionized. This makes light come out of the tube. The color of the light comes from the gas inside the tube. The name “neon” comes from the written form of “neon light,” which people call the orange-red light that the rare gas neon gives off. But these colors can also be made with other gases, such as hydrogen (red), helium (pink), carbon dioxide (white), mercury vapor (blue), etc.

LED Non Lights, Version 2.0

LED neon tube lights are long, straight, and uniform lights that can be bent. They are made of high-brightness SMD LED strips covered in PVC, silicone, or PU (Polyurethane) to spread the light.

What’s different about LED neon tube lights?

First, the LED light source helps to keep the voltage low. A big plus is that it doesn’t use much energy. It uses less than 15W of power per meter and works well even at 24Vdc.

Strong luminosity. The light source is made of ultra-bright SMD LEDs, and there are 121 LEDs per linear meter to ensure the light is bright and even.

The LEDs used in led neon tubes can work up to 50,000 hours. In addition, unlike traditional glass neon lights, the silicone/PVC/PU gel won’t break.

The LED neon lights can be bent and cut with a minimum diameter of 5 cm.

LED neon can be used safely because it runs on 12V or 24V and won’t break like traditional glass neon lights. It also gets rid of heat quickly. For conventional glass neon lights to work, they need a high voltage of up to 15,000V.

The sixth benefit is that it is easy to set up and move around. You don’t have to worry about breaking in transit because it has an LED bulb and a PVC/silicone/PU housing that can handle shocks. Put together the clips or channels for installation, and then push the LED flexible neon into them.

What are the benefits of LED Neon Lights compared to regular neon lights?

Creating traditional neon lights with glass tubes, high voltage electricity, and inert gas is complicated and very expensive. LED neon lights with an innovative design, such as a PVC, silicone, or PU housing wrapped around the LED light source, proprietary optical design technologies, and a tailored housing design to maximize light output and ensure even lighting. LED neon tubes are easy to make and don’t cost much.

Two, LED neon lights are brighter than traditional neon lights.

Third, LED neon lights last longer and work more reliably. LED neon flex lasts a long time. Its LED light source and PVC/Silicone/PU housing allow it to work up to 30,000 hours.

Fourth, traditional glass neon lights often need more than 20W of power per meter of length, while LED neon flex lights only need a minimum of 5W per meter.

To get the gas inside the traditional neon light glass tube to light up, you need a voltage of 15000V, much higher than the 220V/100V used in standard bulbs. In addition, you need to use more than one glass tube to get a specific color. To use more than one color, you need to buy more sets of glass tubes.

The typical shape of a neon sign has to be planned ahead of time and can’t be changed once production has started. LED neon tube lights can be bent and cut to size on site. They come in many colors, such as white, tunable white, RGB, RGBW, DMX512 Pixel, and more.

On top of that, LED neon lights are safe because they have low voltage (12V or 24V), can withstand shocks, and don’t give off much heat.

Conventional neon lights last less long, cost more to run, and can only be used at room temperature because the voltage has to be raised when turned on. LED neon tube lights are some of the best when it comes to how much power they use and how much heat they make. In addition, it can handle high temperatures and take the shock of being dropped.

How do you make LED Neon Lights?

In the first step, LED flexible strip is made. This strip is the primary light source for the neon signs in the rest of the article.

In the second step, you will put silicone around the LED strip. You can attach the silicone case in one of two main ways. The first way is to extrude an LED strip made of silicone. You could also make the silicone tube and put the LED strip by hand.

How to set up the silicone for led neon light tubes

First, silicone is put together.

Silicone is a solid material. Most neon lights use a milky white silicone for diffusion or a white silicone for blocking. LEDYi’s neon lights are more cutting-edge than its competitors because they use three silicone colors. The third color is transparent and is used when cutting windows so that workers can easily see where they are cutting.

Silicone is just one material that can be used to make things. For example, mixing in a certain amount of diffusion powder changes the color of silicone. More diffusion powder can make the silicone whiter and cut down on how much light it lets through.

Second, rolling LED strips are attached to the payout frame so the extrusion process can begin. The brightness, color, and order of this LED strip are all set by a table.

Third, the LED strip and silicone are fed through the holes in the die that have already been put together. When the “Operate” button on the electronic control box is pressed, the machine wraps the silicone around the LED strip.

Fourth, after the silicone has been put on the LED strip, the machine will push it into the vulcanizing oven, where it will slowly harden and take the shape of the mold. So that the LED beads don’t melt, the range is kept at a specific temperature. Finally, after the led neon has been vulcanized, it is turned on by a tractor.

How to make LED neon tube lights by hand

First, silicone neon sleeves can be made with extrusion machines or bought from other companies. Silicone neon sleeving can be made using the same extrusion process described above for LED strips and silicone. The silicone neon sleeve no longer has an LED strip inside of it.

The second step is to put the prepared LED strip into the silicone neon tube by tying it to the tube with the wire and then pulling it out of the other end of the tube.

Manual Extrusion vs. Integrated Extrusion of Silicone

Since the led strip and silicone are both extruded simultaneously during the silicone extrusion process, it is possible to make led silicone neon that is longer, and in theory, as long as you want. However, because the voltage will drop and it will be hard to move, LED strips shouldn’t be longer than 50 meters. Most of the time, a manual route can’t be longer than 5 meters. Too much resistance is made by the led strip and silicone neon tube for a draw of more than 5 meters.

Because the silicone is pushed out as a single piece, the LED strip inside the silicone neon tube is not free to move around. As a result, the LED strip and silicone neon tube movement will resemble the old way of doing things.

Integrated silicone extrusion is a much better way to do things than using your hands.

Due to the time and money, it takes to set up the machine, making small amounts, like 1-meter samples, with the one-piece silicone extrusion process can be expensive and take a long time. The manual method is easy if you already have silicone neon tubes on hand. All you have to do is put the LED strip into the tube by hand.

How can you be sure that LED Neon Flex Lights will work as they should?

First, ensure that all the LEDs, resistors, and ICs in the LED strip you’re using as a light source are brand names.

Second, ask the manufacturer for the LEDs’ LM80 test results. Suitable LEDs should have an L80 lifetime of at least 50,000 hours.

Third, use a double-sided, pure copper PCB that is 2oz or 3oz thick for the light source of the LED strip.

Fourth, make sure that the housing of the LED silicone neon light is made of high-quality silicone that is flame retardant, resistant to UV light, and won’t rust.

Fifth, ensure the LED silicone neon has all the product approvals it needs (such as CE, RoHS, UL, etc.).

Make sure that the finished silicone neon lamp has as small a range of color temperatures as possible. For example, our LEDYi’s color temperature rarely changes by more than 100K.

Make sure that the CRI of your silicone neon light stays high. In general, it’s better to have a higher color rendering index. For example, all our LEDYi silicone neon lights have a CRI of 90+.

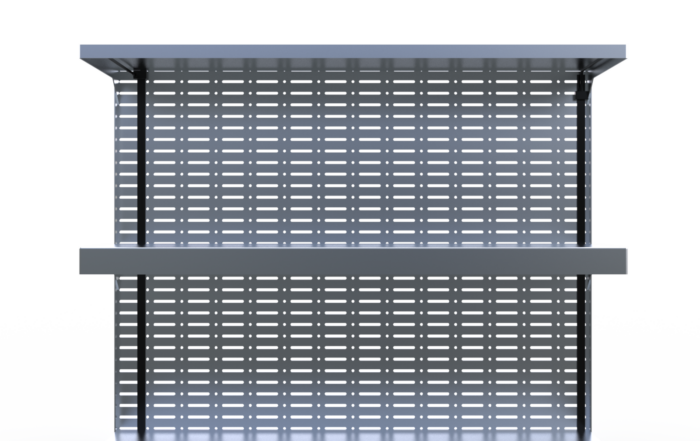

As a result, it’s essential to ensure that the led silicone neon comes with various attachments. Solder-free plugs, integrated injection plugs, plugs for varying wire outlet directions, mounting clips, and aluminum light fixtures are only a few examples.

Verify that you may personalize, OEM, or ODM the LED silicone neon.

The best way to set up your LED Neon Lights

Beginning with a Length Measurement

- Locate the cutting point on the LED Neon Tube

- Modify the LED Neon light by cutting it to size

- Connect the LED neon connectors

- Plug in the LED neon sign.

- Follow these steps to install an LED neon light:

- Screw the mounting clip or mounting channel into position

- Insert the LED neon light into the mounting clip or mounting channel

- Turn on the LED neon light for a test

Where do I plug in my LED Neon Lights

Make sure the LED Neon Tube you’re using is compatible with the voltage you’re using

- If necessary, locate a power source and controllers that are compatible.

- Put up your LED Neon Tube wherever you want it

- Vonnect the power source and the controls

- Link the LED Neon Tube Light to its power source and any necessary controls

- Turn on the light

What is the answer to the question, “Can I cut LED Neon?”

Can you? A: Why, yes, you can. However, LED Neon Tube Lights must be cut on the designated cut line. You can make out the cut markings (scissors or a black line) through the neon window.

Can I cut LED Neon tubing at any point?

The answer is no; you can’t. LED Neon lights must be snipped along the drawn line. The LED neon clear window reveals the “scissors or black line,” indicating where the material was snipped. There is a cut mark on the LED Neon Light; if you cut it anywhere else, you’ll damage the PCB, and the LED Neon light will stop working.

Can I make a hole in the intelligent LED Neon lights?

You have my permission to do so. However, the clever LED Neon tube must be sliced precisely at the score line. Through the neon window, you can make out the “scissors or black line” markings that indicate where the material was snipped.

Where do I find a place to cut LED Neon tubes?

The LED Neon light can be cut on the dotted line. Then, through the neon window, you can make out the “scissors or black line” markings that indicate where the material was snipped.

How about the LED Neon tube?

If you’re wondering whether LED Neon lights are waterproof, the answer is yes; it has a rating of IP67 or IP68.

How can I connect LED Neon tube strips?

First, you’ll need to snip some LED Neon tube.

Second, connect the LED Neon tube lightswith the solderless connectors.

The next step is to connect the LED Neon light to the solderless connections.

Activate the test light in Stage 4

What is the function of the LED Neon tube?

LED neon lights, which employ LED strips as their light source, include a silicone outer shell that helps diffuse the light and eliminate hotspots.

What is the lifespan of LED Neon lights?

The quality of the light source LED and the heat dissipation effect of the LED neon tube determine the LED neon’s lifespan, typically between 30,000 and 5,000 hours.

Do LED Neon tube lights have a lower carbon footprint?

Yes. LED neon lights provide many advantages over traditional neon bulbs, including lower power consumption, indestructibility, low operating voltage, safety, and a long lifespan.