For years, LED strips have been the “it” thing when providing ambient lighting in various settings you can accomplish independently. That’s why we’re keen on investigating the newest type of LED strip lighting—the COB flexible led strip.

To begin, what is a COB LED Strip?

In the realm of LEDs, the acronym COB signifies the direct packaging of the LED chip onto the circuit board (PCB). LEDs used in flexible strip lights are often called flip-chips or “Chip on Board” LEDs.

LEDs built using a flip-chip technique are extremely simple. In a typical SMD (Surface Mount Device) LED, the LED chip is housed in a Lamp bead holder, and the phosphor coating is applied on top. To create the COB LED strip, the ‘flip chip’ only leaves the LED chip, yellow phosphor cover layer, and connection pads in place.

COB LED Flex Strips: Their Pros and Cons

Now that you know how this new COB-led strip is manufactured, it’s time to evaluate its benefits and drawbacks.

Benefits:

Even without aluminum profiles, there isn’t a single LED light point.

The consistent lack of illumination along the length of conventional LED strips is a common criticism leveled at them. The source of the light is indicated by a bright spot (or “lighting dot”) somewhere along the strip. Unlike a jumble of lighting dots, a smooth light source gives off a warmer and more aesthetically pleasing glow.

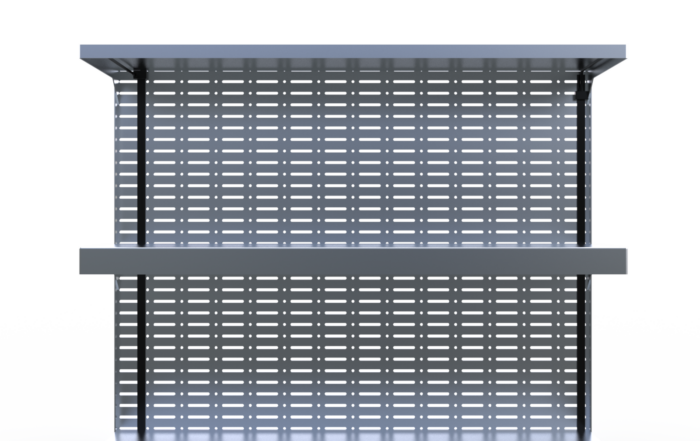

Due to the proximity of the larger diodes in 5050 SMD flex strips, the light emitted is diffused and uniform across the illuminated surface, even at a greater distance. However, the hot spot is an obstruction that can’t be overlooked if the light is too close to the surface or if the strip is in plain sight.

Picking out any hotspots on a 480 chip/M COB flex strip is a significant challenge. The light from this strip is uniform and gentle along its length. As a result, the human eye is more attracted to it, and the environment is illuminated consistently by even light in which no lighting dot is present.

Looking at the strip’s reverse, where the flip-chip LEDs are more readily apparent, is the only practical way to spot the light source. At a brightness of about 5%, you can finally make out each LED in the strip. This is why COB flex strips are so helpful in situations where

- It is impossible to obscure the led strip from view.

- The light bar is less than two feet from the surface being illuminated

- Surfaces that reflect light, such as granite and glass, are abundant

- In situations where a brilliant neon effect is required

Enhanced adaptability

The thin diodes and even loading make this strip significantly more malleable than others. In addition, due to these diodes’ small size and proximity, the strip’s surface is never uniform.

This consistency facilitates a straightforward installation process, as you won’t have to work around any stray 5050 SMD LEDs. In addition, they can now bend and swivel more efficiently, allowing them to access previously inaccessible areas of your application.

Safer, less prone to disruptions

The chip on a COB strip is soldered directly to the FPCB and does not include a gold trace. The gold wire contained within conventional SMD LED beads causes many issues. The chip won’t light up because the gold wire is too delicate and easy to break.

The LED COB strip’s circuit design incorporates three chips connected in a series and parallel fashion for two steps, respectively. This one-step strip will still work if a pair of bad chips are inside the group. And COB a meter of chips how big 480, even if 1-2 chips do not light, will not produce dark areas, will not affect the use.

Unlike the standard SMD LED strip, which only has a CUT if all the lamp beads are defective, this one does not light up, so the cutout is quite visible.

Large beam angle

The traditional SMD light strip luminous angle is 120 degrees, while the COB light strip sharp angle is 180 degrees.

Anti-vulcanization

Chip-on-board (COB) LED strips cannot be vulcanized like standard surface-mount diode (SMD) LED strips because they lack the necessary gold wires. In the SMD LED lamp bead, the chip has one electrode connected to the LED bracket with gold wire and the other electrode connected with silver glue.

Unfortunately, silver readily forms silver sulfide when exposed to sulfides. Therefore, the LED’s blackening and luminous flux are diminished.

Improved ability to resist static electricity

COB LED strips are more resistant to static electricity than standard SMD LED strips.

Drawbacks:

Simply put, there is no commercially available COB-led strip binning machines. In addition, all current manufacturers of COB-led strips only sample occasionally to check color accuracy. Thus, it is challenging to guarantee that 100 percent of COB-led strips are within a 3-step color tolerance.

Diminished light output

However, the current efficiency of COB-led strip lights is only about 120LM/W. Therefore, the COB-led strip is inappropriate if you require greater light efficiency.

Reduced luminous efficiency

COB-led strips can handle up to 30W per meter, but experts advise sticking to the lower 15W/m limit. If the power goes above 15W/m, the heat generated by the chips becomes tough to dissipate because too many of them per square meter. As a result, the life expectancy of COB led strips will be reduced.

The COB Flex Strip’s Distinct Traits

The benefits and drawbacks of COB flexible light strips should be clear by now, so let’s discuss this product’s finer points. Lots of this will sound familiar if you’re familiar with LED strips, but there are some differences during this type of strip that you should test out before using COB strips.

Separate and Join

Our COB led strip cutter works perfectly with this strip. The strip has cut lines every 50mm (24) / 25mm; please follow them exactly (12V). Therefore, you can modify the strip’s length to fit your needs and create spaces where necessary.

In most cases, reusing the strips after cutting them requires soldering the ends together, but if this is impractical, our COB strip connectors are another option.

Adjustable

Led strips with COB components can be dimmed like those with SMD components.

To achieve dimming, you can use DALI, Triac, PWM, and 0-10V power supply with COB-led strips.

Choices of Color

White light is available in a wide range of color temperatures, from 2700K to 3000K to 4000K to 6000K and beyond.

Colorful light: Red, green, blue, yellow, pink, etc., are available.

The wavelength of white, red, green, and blue light can be adjusted.

P grade COB

There are several different waterproofing options, including IP20 for non-waterproof, IP52 for silicone drip, IP65 for silicone sleeve, and IP67 for silicone sleeve.

COB LED Strip Install Guide

- Make sure the area is spotless before installing the COB-led strip light.

- Miniaturize the COB led strip light you intend to install.

- Tear the 3M backside of the COB led strip light.

- Put the COB light strip wherever you want by sticking it there.

- Join the power source to the COB led strip’s lights.

- The COB led strip light comes with a connector or terminals that can be soldered for a secure connection.