COB LED Strips stands for “Chip on Board,” or “COB,” is a term used in the world of LEDs to describe the process of putting the LED chip itself in a package that is directly attached to the circuit board (PCB). The LEDs in flexible strip lights also called “Chip on Board” lights, are sometimes called “flip-chips.”

Flip-chip LEDs are very easy to make compared to other types of LEDs. Take a look at a typical SMD (Surface Mount Device) LED. The LED chip is held in place by lamp beads, and a phosphor coating protects the chip from the outside world. The COB LED strip has a “flip chip” that removes all the parts that aren’t needed, leaving just the LED chip, a yellow phosphor cover layer, and connection pads.

The pros and cons of COB LED Flex Strips

After you understand the basics of how this new COB-led strip is made, you can determine its pros and cons.

Advantages:

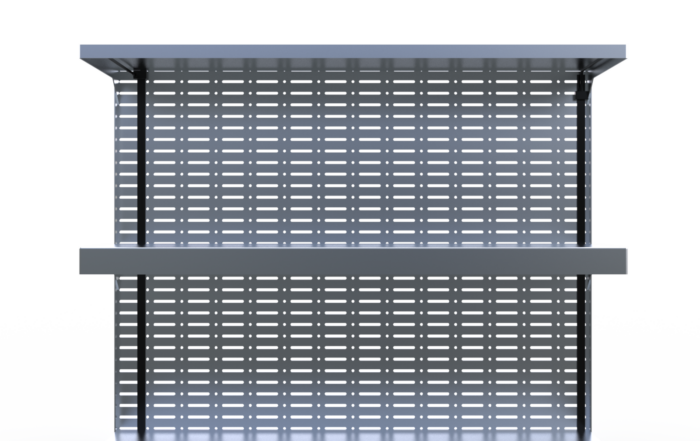

There is not even a single LED light point because there are no aluminum profiles.

A common complaint about LED strips is that they have light spots along their length. A lighting dot is a spot of light in the strip that shows where the light is coming from. A smooth light source is better than one with faults because it gives off a softer, more pleasing light.

Because the bigger diodes are so close, the light from 5050 SMD flex strips is spread evenly over the lit area. If the light source is too close to the surface, or if the strip is visible, the human visual system will be unable to avoid the hot spot.

When working with a COB flex strip with 480 chips/M, it can be hard to find the “hot spots” of each chip. Down this strip, the light from it is even and soft. The human eye is more drawn to it, and the environment is better lit when the light is even, and there are no bright spots. The only practical way to see the light source is from the back of the strip, where the flip-chip LEDs are easier to see. To know each led on the strip, the brightness must be reduced to about 5%.

Because the diodes are so small and the weight is spread out evenly along the strip, it can bend much further than other flexible strips. Because these diodes are small and close together, the strip’s surface is never the same. Setting up the strips is easy because there won’t be any loose 5050 SMD LEDs to worry about.

Because the chip on a COB strip is soldered directly to the FPCB, it does not have a gold wire. The gold wire inside standard SMD LED beads is the cause of many problems. Because the gold wire is so small, it is easy to break. This is why the chip doesn’t light up.

The COB strip’s circuit is made up of three chips, connected one at a time in parallel, then in series, and then in series again to make one step. Even if two chips inside this one-step strip go wrong, it can still burn. So even if only one or two of the 480 COB chips in a square meter don’t light up, this won’t cause dark spots or make the fixture less useful. Unlike the standard SMD strip, a CUT, this one will only light up if all of the lamp beads are good enough, making a dark area.

Wide degree lighting

The light from a COB light strip can be seen from 180 degrees, while a standard SMD light strip can only be seen from 120 degrees.

The downsides:

The biggest problem with COB-led strips is that the colors are complex to keep the same. Simply put, there is no COB-led strip binning machines on the market now. All current makers of COB-led strips occasionally sample to check color accuracy. Even worse, it’s hard to be sure that every COB-led strip is within a 3-step color tolerance.

The current efficiency of COB-led strip lights is only about 120LM/W. Therefore, there are better choices than the COB-led strip if you want better lighting efficiency.

Using more than 15W per meter of COB led strip’s maximum power is not advised. If the power goes above 15W/m, the chip’s heat becomes tough to dissipate because of the high density of chips per unit of length. This will make COB-led strips last less long.

COB Flex Strips: What Makes Them Different

The benefits and drawbacks of COB flexible light strips should be clear by now, so let’s dive into the nitty-gritty of this product. Some of this may sound familiar if you’re already familiar with LED strips. Still, some critical distinctions throughout this strip type warrant a trial run with the guidelines provided below before you commit to COB strips.

Splice and Join

This strip can be slit using a COB-led strip cutter, as our other strips can. Please only make cuts at the pre-marked 50mm (24) / 25mm intervals on the strip (12V). You can modify the strip’s length to fit your needs or create spaces as necessary. The snipped strips can be reused and are ideally linked through soldering, but we offer COB strip connectors if that’s impossible.

Dimmable

Like traditional SMD led strips, COB led strips can be dimmed.

You can utilize a DALI, Triac, PWM, or 0-10V dimming power source to achieve dimming with COB-led strips.

Conclusion

COB-led strips are a good choice if you want to light up a room without making hot spots. However, only a conventional SMD-led strip is a viable option if you require high lumens, high luminous efficacy, or rigorous color constancy, such as 3-step Macadam color tolerance or 2-step Macadam color tolerance.ere